Resolution adapted to the requirements of the part

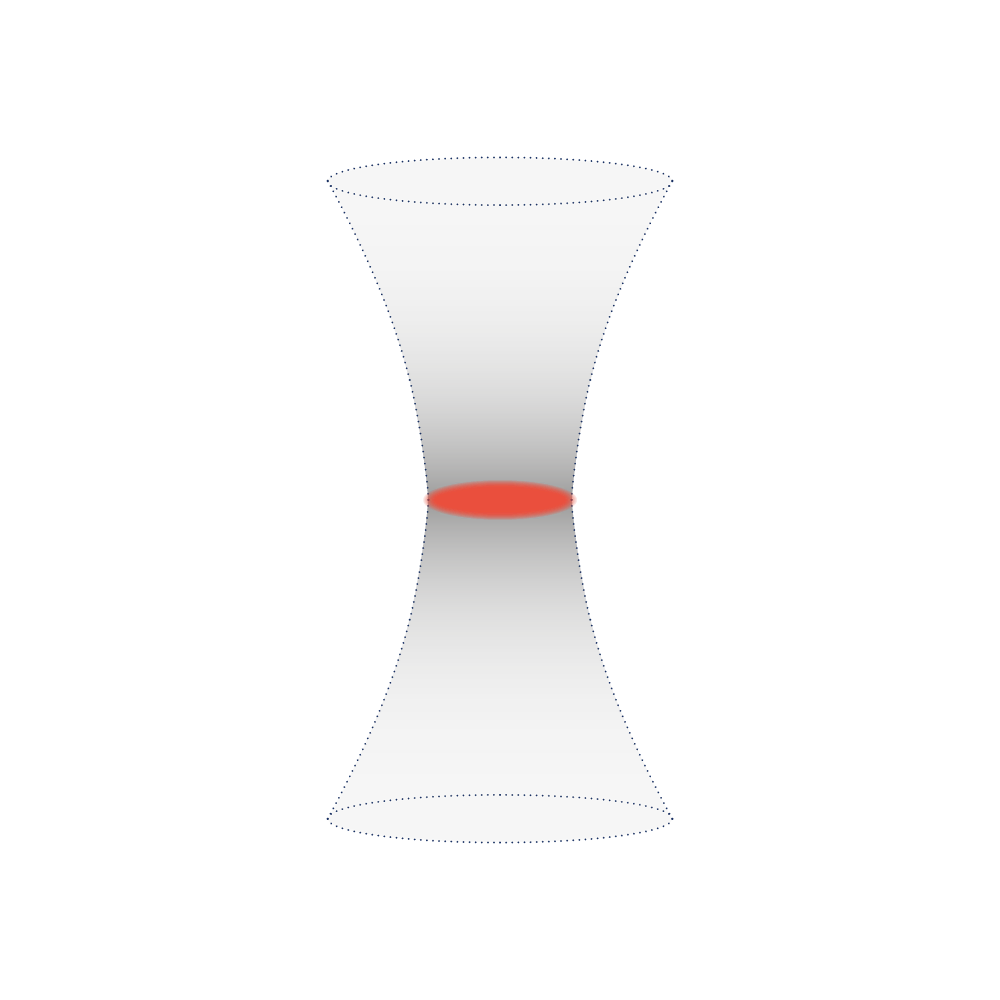

Substantial improvements in throughput are achieved using the patented UpNano Adaptive ResolutionTM technology. This innovative software automatically categorizes selected geometry into high and low-resolution areas, adjusting the laser voxel size accordingly. The laser focal point is then tailored to the specific requirements of each segment: enlarged for bulk segments and precisely focused for the outer shells and fine details. This adaption can, metaphorically speaking, be described as a marker pen with two sides: the thin tip for details and the surface of the structure, and the thick side for swiftly filling in the inner areas.

UpNano’s printing systems feature powerful laser sources that enable simultaneous adjustment of laser power, ensuring homogeneous polymerization rates and consistent material properties. This not only enhances increase throughput by speeding up the printing of internal areas but also ensures that the highest resolution is applied precisely where needed. Alternatively, customers have the flexibility to manually customize resolution levels for specific areas and segment components according to their requirements.

High-volume segments

The laser focal point is enlarged, optimizing throughput while preserving the mechanical properties of the printed component in the so-called coarse mode. In this printing mode, the laser focal point is widened through the interaction of hardware and software, with the laser power adjusted accordingly.

High-resolution segments

The laser is tightly and precisely focused to achieve the highest possible resolution in fine mode. Depending on the selected objective, this enables the attainment of structural details as small as 200 nm, fully leveraging the capabilities of 2PP technology.

Outline mode

UpNano’s proprietary outline mode ensures high resolution and low surface roughness. The outlines of solid printed components are structured with utmost precision to fully exploit the potential of the selected objective. This mode is especially suitable for producing lenses with a surface roughness as low as <10 nm. By utilizing this mode, economical production of larger lenses is achievable while maintaining exceptional surface properties.